RPP FAQ

RPP faculty frequently receive questions regarding rice processing and quality. As questions are received by the faculty, we will post them here. To submit a new question, please contact Dr. Griffiths Atungulu at atungulu@uark.edu.

Drying

Are there algorithms specific to rice that should be used in grain bin monitoring? Can the drying and storage temperature of rice at temperatures above 100°F affect quality?

Algorithms used in drying and storage rely on equilibrium moisture content (EMC) data, which is specific to grains. For example, the utilization of soybean data to forecast drying or storage scenarios for rice would be inaccurate due to the distinct equilibrium moisture content relationships between the two. For on-farm drying using a cable system, there are typically two options: continuous drying within a specified EMC range or drying with supplemental heating, which typically involves increasing the incoming air temperature by 5-10 degrees above ambient.

Ideally, drying rice at near-ambient conditions is preferable for maintaining quality. While a temperature of 100°F is below what commercial crossflow dryers commonly use, significant compromises in quality are not expected at this temperature. However, prolonged exposure to such conditions may lead to reductions in head rice yield.

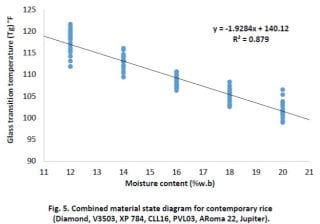

The provided figure (below) is from a recent publication in BR Wells (Ameyaw Owusu et al., 2022); it illustrates glass transition temperatures versus rice moisture, aiding in predicting scenarios where the rice material may change phases thereby inducing stresses leading to breakage. As long as rice moisture remains within a certain range (approximately <20-21%), there should be no stress induced on the kernel with 100°F air temperature. Additionally, it’s important to note that air temperature is typically slightly higher than grain temperature by a few degrees. So we expect the grain to be at slightly lower temperature than 100 F.

RPP scientists have previously validated in-bin cable performance, with the simplest method being to compare the grain’s moisture content closest to the cable, as registered using cables, with lab moisture plus oven methods. This comparison will quickly determine the accuracy of the algorithms. Our studies suggest that depending on the foreign matter content in rice, cables may overestimate moisture by a few percentage points (2-7).

Milling

Why is there a delayed deployment of destoners in the milling process after husking? Additionally, at which stage in the milling line are magnets typically employed for the removal of metallic substances?

The rationale behind the placement of destoners after huskers is attributed to the increased abrasiveness of unhusked rice compared to brown rice. Placing destoners after husking is a strategic measure to mitigate wear on the destoners. Given the considerable cost associated with stone polishers, efforts are made to preserve their longevity. Generally, magnets designed for the extraction of metallic fragments, such as screws, etc. are positioned before the stone polishers to prevent damage or breakage of the stones. The specific placement of magnets along the milling line varies among companies, with some incorporating multiple magnets; however, a common practice involves siting them before husking and preceding the packaging phase.

Quality

Does medium to long-term storage of milled rice at sub-zero temperatures impact the final product texture/taste/cooking characteristics/etc. in any way?

In general, no changes will be expected on milled rice cooking quality when stored at sub-zero temperatures as long as proper conditioning is done during rewarming the rice back to normal condition.

Major concerns are related to how the milled rice is handled after storage in the super low temperatures. There have been cases of condensation happening on the rice kernels if the rewarming process is not done well. Such condensation results in rice cracking. From our studies here at the Rice Processing Program, we have realized that condensation can happen on cooled rice depending on the conditions of the air surrounding that grain after cooling. When the surface of the cooled kernel’s (endosperm) absorb moisture above some level the kernel goes through a phase differential where the core remains in the glassy state and the surface transitions into the rubbery state. That phase differential is known to induce tensile and compressive stresses that ultimately cause micro-fissures to be created within the rice. These micro-fissures weaken the milled rice and cause some breakage of the kernels during handling. You may see less head rice after the chilling aeration compared to the original sample. Care must be taken to rewarm the rice without condensation. Condensation will easily happen if the high humidity warm air encounters the cold rice after cold storage.

The article Rice Quality Preservation during On-Farm Storage Using Fresh Chilly Air by Shuso Kawamura, et. al. addresses a similar issue. The research project was supported in part by Grants-in-Aid for Scientific Research from the Japan Society for the Promotion of Science. The study involved both lab- and field-based investigations. The field experiment was financially supported by the Hokkaido Agricultural Structures Council. Although the rice types tested are not exactly like ours or cook in a similar manner due to differences in amylose content, there is a possibility that the results reflect what we expect with ours rice types, to some extent.

In the study rough rice was stored at temperatures below ice point. Freezing temperatures and extents of freezing injury of rice with various levels of moisture content were studied, and effects of temperature below ice point during a four-year storage period on the physiological properties of rice were investigated.

What was observed is that rice with moisture content of less than 17.8% did not freeze even at a temperature of –80°C (-112 F). That means that for the temperatures you plan to store rice we do not expect the rice to freeze. In that study it is also reported that the rice maintained its textural characteristics upon cooking. They measured textural properties by evaluating the hardness and stickiness of the cooked rice. This result show that there was no significant deterioration of starch in rice. Because most other functional characteristics in rice would depend on the rice starch properties, overall, we expect preservation of the other rice quality attributes.

Freezing injury did not occur in any of the rice grains stored at 2°C (35.6F). Freezing injury was evaluated by monitoring germination rates. Germination rate of rice grains stored at 2°C was almost 100%. However, freezing injury occurred in all the rice grains of high moisture (26.5% m.c.) stored at the temperatures below –20°C (-4F) because the germination rates were 0%. (Figure 4) within the article shows this. Because the rice we are dealing with is dried there is no need for concern about the freezing injury in farm silos at temperatures you mentioned.

Another quality index to look at is Fat acidity which is responsible for rancidification of rice. Lipase hydrolyzes fat in rice grains to fatty acid. When the activity level of lipase in rice is high, the amount of free fat acidity increases during storage. This increase in the amount of free fat acidity causes deterioration of the quality of rice during storage. Because the rice we are dealing with in your case is milled, it has little fat to begin with. I assume equal or less than 0.4% surface lipid content for standard degree of milling. From the study I noticed that the free fat acidity of rice stored at temperatures below 5°C (41F) was almost the same as that at the beginning of storage (Figure 6). However, the free fat acidity of rice stored at 25°C dramatically increased during storage. Again, for your storage temperatures this is not an issue to be worried about.

Generally, the hardness of cooked rice increases, and the stickiness of cooked rice decreases during storage. The texture property (hardness/stickiness ratio) increases accordingly as rice ages. The changes in the texture of cooked rice are caused by deterioration in rice starch. There was no change in hardness/stickiness ratio of rice stored at temperatures below 5°C (Figure 7).

In summary: No grain with a moisture content of less than 17.8% is expected to freeze at a temperature of –80°C (-112 F). There is therefore no need for concern about the freezing of rice stored at a temperature below ice point. Also, low temperature maintained the vitality of rice, minimized physiological activities and starch deterioration in rice, and preserved rice quality.

How can lipid deterioration in milled rice be assessed?

Measuring lipid deterioration in milled rice typically involves assessing the changes in lipid content and quality over time. Here are a few methods commonly used to measure lipid deterioration in rice.

1. Peroxide Value (PV): The peroxide value is a widely used method to measure the primary oxidation products of lipids in rice. It quantifies the concentration of peroxides, which are formed during the initial stages of lipid oxidation. A higher peroxide value indicates increased lipid deterioration and oxidative rancidity. The measurement is typically conducted using chemical titration methods or enzymatic assays.

2. Thiobarbituric Acid Reactive Substances (TBARS): TBARS assay measures the level of malondialdehyde (MDA) and other secondary lipid oxidation products in rice. It is a commonly employed method to assess lipid oxidation and rancidity. The TBARS assay involves reacting the MDA present in the sample with thiobarbituric acid (TBA) to produce a colored compound that can be quantified spectrophotometrically.

3. Free Fatty Acid (FFA) Content: As lipids deteriorate, they break down into free fatty acids. Measuring the free fatty acid content in rice can provide an indication of lipid deterioration. The FFA content is often determined through acid hydrolysis of the sample, followed by titration to determine the amount of free fatty acids present.

4. Oxidative Stability Index (OSI): The oxidative stability index measures the resistance of lipids in rice to oxidative degradation. It typically involves subjecting the rice sample to accelerated oxidation conditions, such as elevated temperature or exposure to an oxidizing agent, and monitoring the formation of volatile degradation products or changes in lipid properties. The OSI value can provide insights into the susceptibility of lipids to deterioration.

These methods require specific laboratory equipment and expertise to perform accurately. If you are interested in measuring lipid deterioration in milled rice, it is recommended to consult with a food testing laboratory or analytical service provider.